PTFE sheet

December 28, 2019

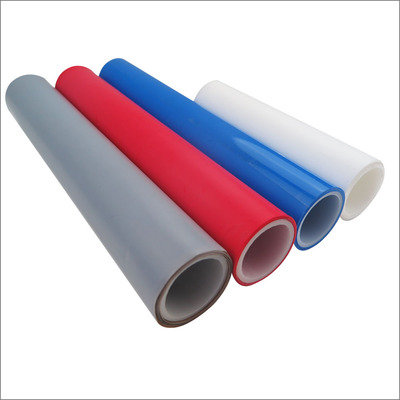

PTFE Tubes and Rods

December 30, 2019PTFE Film provide a low-friction, non-stick surface suitable for use in high-temperature and high-dielectric applications. PTFE Film are available in roll form or can be supplied etched one-side, etched two-side or with a self-adhesive acrylic backing (pressure-sensitive tape).

Applications include capacitor films, cable harnesses, spacers, electrical insulation components, PCB’s, flexible circuits, cap liners, plungers, stoppers, protective liners, gaskets, diaphragms, semiconductor processing components, expansion joint liners and sleeves, fuel cell seals and separators, solar panel (photovoltaic) modules and surface protection liners.

PTFE films are used to provide a high temperature, chemical resistant material in a number of applications.

Our cast films are made up of very thin layers which have been individually deposited, sintered and fused together to produce a material with more uniform properties than can be achieved by any other manufacturing process.

These PTFE films offer great electrical properties, and are additionally engineered to meet the requirements of demanding mechanical and chemical needs

Skived films and foils are semi-finished products, available with a maximum thickness of 5mm. For thickness larger than 5mm, we direct you to section PTFE SHEET. Width and length are according customer specification. The films and foils are skived from large PTFE blocks (round). For applications in which the PTFE film or foil must be bonded, we recommend a one side etched (or two side) etched PTFE film or foil.

Key properties of PTFE

- Excellent chemical resistance

• Working temperature -190°C to +260°C

• Greatest resistance to fatigue

• FDA approved

• Flame resistant – UL94V0

• No stick

• Low friction

• UV-resistant (does not age)

• Not hygroscopic (water absorption < 0,01%)

• Very good dielectric dielectric insulation properties

Properties of PTFE can be improved by adding additives as carbon, graphite, glass etc.